Advantages Of Gd T Over Conventional Tolerancing

Some of the advantages of using gd t on engineering drawings and product data sheets are that it.

Advantages of gd t over conventional tolerancing. More information about the gd t fundamentals class. It uses a symbolic language on engineering drawings and computer generated three dimensional solid models that explicitly describe nominal geometry and its allowable variation. A datum is just a fancy word for saying which specific feature on a part will be used as a reference zero for tolerance calculations dimensional measurement and most importantly from where the feature s manufacturing should build from to ensure a consistent part.

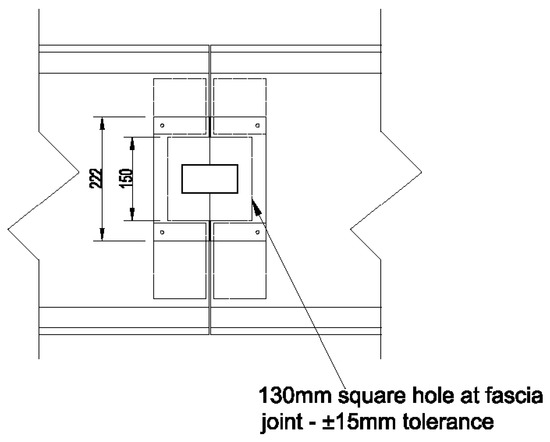

Eliminate guessing at product tolerancing resulting in fewer prototype iterations and drawing revisions. Understanding of gd t locating datums is helpful. Provides a concise way to describe a reference coordinate system.

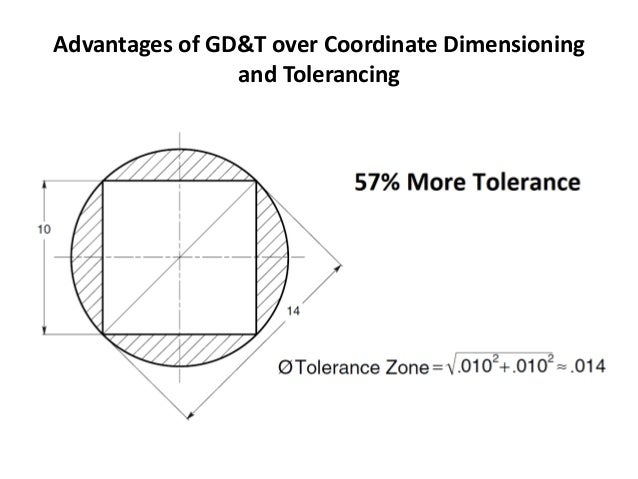

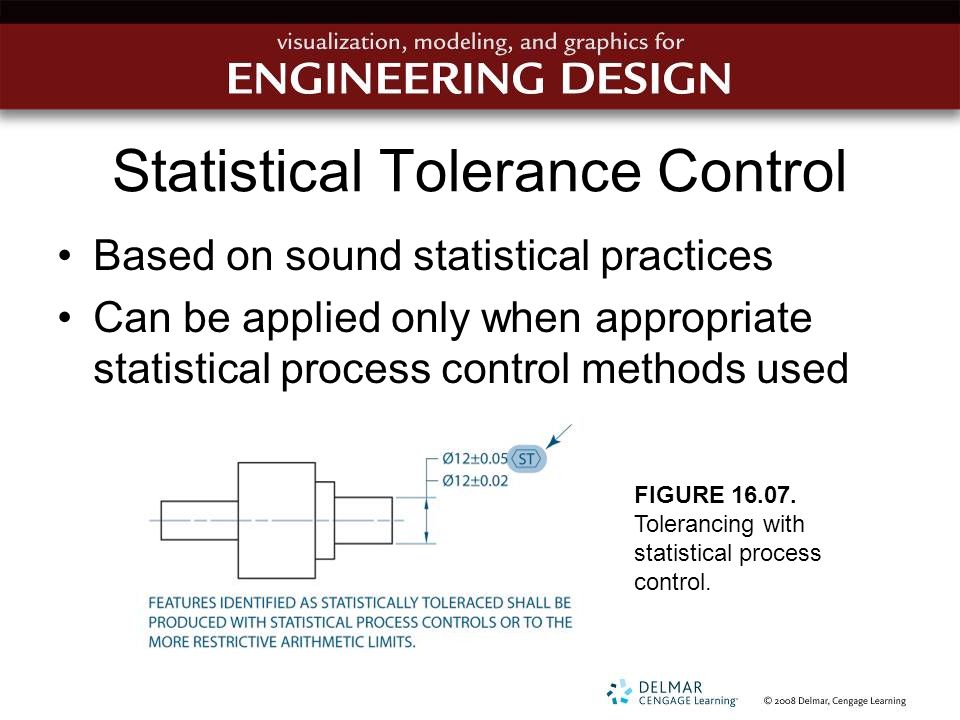

Allows for more tolerance this last benefit of gd t is surprising to many people. Specifies dimensions and related tolerances based on functional relationships. The gd t symbols substitute for those notes and greatly reduce the chance of mistakes.

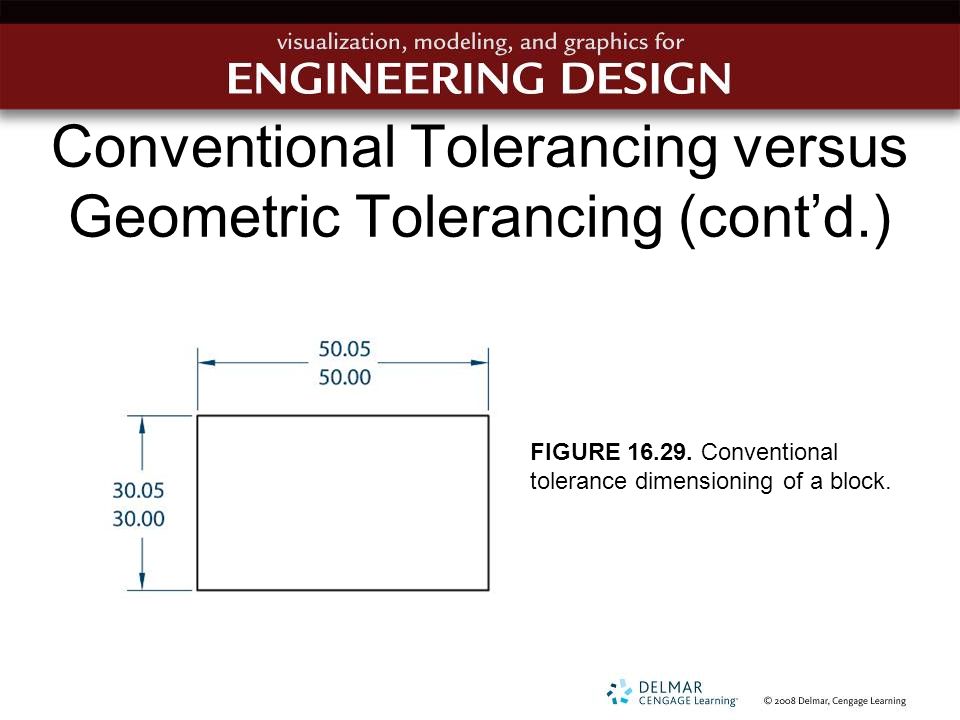

Geometric dimensioning and tolerancing gd t is a system for defining and communicating engineering tolerances. Geometric dimensioning and tolerancing gd t has been around since the 1940s yet it is unappreciated as a way of finding bad designs before parts get made. Here are some of the advantages gained by using gd t over conventional dimensions tolerances.

They think that using gd t will mean tighter tolerances. The following is a short list outlining the benefits of using gd t. The advantages of using gd t over conventional dimensions tolerances include.

Gd t facilitates an efficient means to communicate specific datum son a part. 1 of a component or assembly to be used throughout the manufacturing and inspection processes. Some distinct advantages of gd t are as follows.

Uses datums and datum systems to define dimensional requirements with respect to part interfaces. A concise way to describe a reference co ordinate system or datums see fig. Specify the maximum available tolerance for manufacturing while protecting feature function.

It tells the manufacturing staff and machines what. Reduced number of notes dimensions and tolerances on a drawing. Geometric dimensioning and tolerancing gd t is the precise language of engineering drawings as defined in asme y14 5m dimensioning and tolerancing.